Powdered Resins

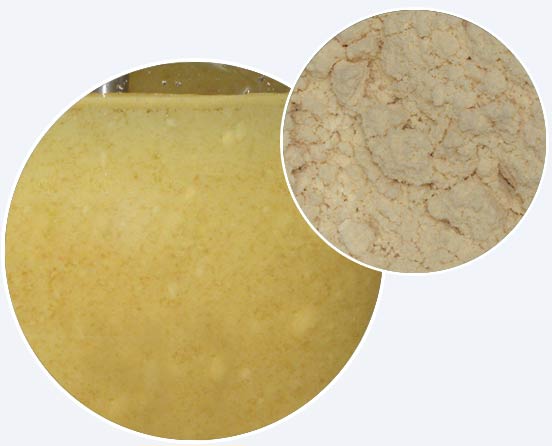

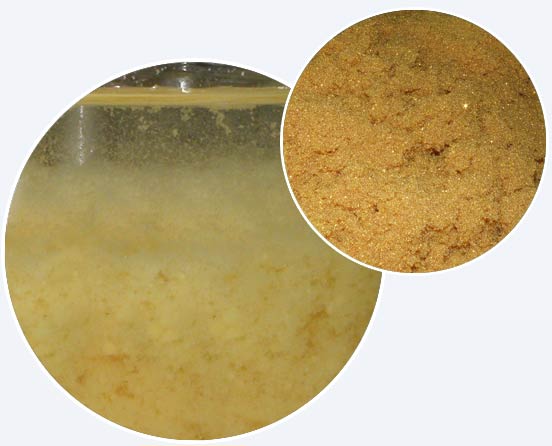

Powdered resins are obtained by grinding special active form ion exchange resins, most commonly in ammonia and hydrogen forms for cation resins and hydroxy forms for anion resins. Purity requirements for the ingredients vary according to the application. The interaction of different particles of cation and anion resin in a watery media (to form a highly developed floc considerably larger than the mass of the individual particles) is possible thanks to zeroing of the electrokinetic potential of each individual particle of resin involved in the interaction.

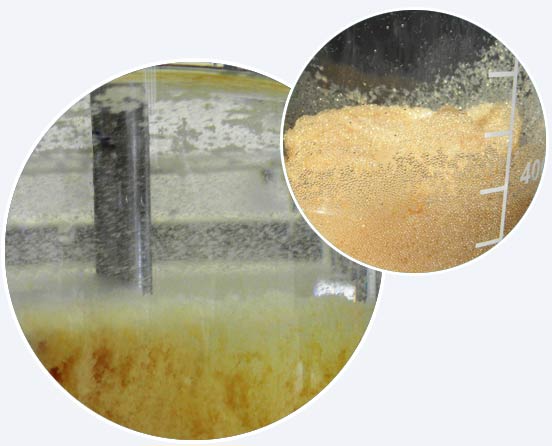

The electrokinetic potential of each particle is influenced by various factors such as particle size, its electrical charge and the resin’s exchange capacity. Powdered ion exchange resins form a compact coat layer unit which performs all the functions of ion exchange, in addition to capture of colloid metal oxides through electrokinetic attraction and physical filtering of larger metal oxides.

This extraordinary mix of capacities made possible by a thin filter coat of a few millimetres (thickness between 6 and 10 mm) firstly requires the use of products with a high level of purity. It is essential that the powdered resins maintain their chemical and physical properties in the long-term. To ensure floc stability, it is necessary to use basic, 100% certified ingredients.