Polycomponent mixtures

and multi-layer precoats

For many years Aqua Chem has been applying innovative methods for using powdered ion exchange resins aimed at solving practical nuclear power generation filtering problems. The experience gained in Italy with powdered resin precoat filters at high temperatures (133°C) to reduce localized ΔP in UP systems has led to the development of excellent granular ion exchange resins used to grind into powder, while applications in neutral pH nuclear BWR systems, even at 80°C, have shown excellent results thanks to use of varying resin mixes similarly to conventional systems in which bead resins are used for specific purposes. The addition of carboxylic powdered resins to the mixture has not only reduced the problem of sulphates leakage to the reactors, but has also allowed considerably longer filter cycles compared to those obtained with conventional powdered strong cation and anion resins mixtures.

We are pleased to report that in several Swedish and U.S. nuclear reactors Aqua Chem’s technology has been preferred and has contributed to limit the disposal of spent powdered resins over a factor of ten.

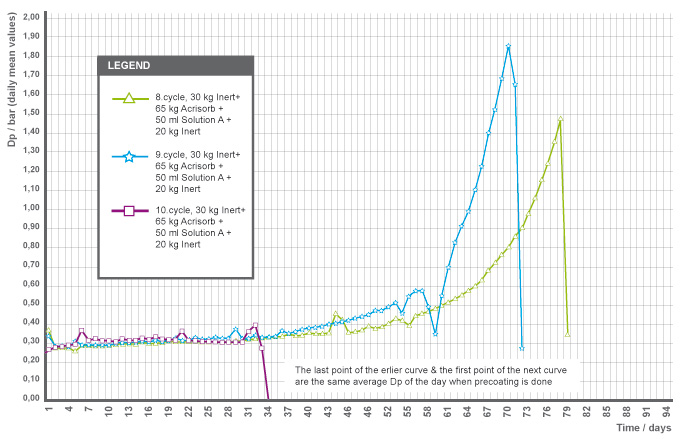

Aqua Chem has also contributed to the introduction of inert polymer fibers to precoat filter systems, in the form of a sub-layer or over-layer for a powdered resin coat. A sub-layer creates a defence which protects the filter elements against resin extrusions at the end of long cycles (up to 100 days) with high ΔP (up to 2 bar at the end of the cycle), while an over-layer protects the filter coat from cracks which would reduce its chemical properties.